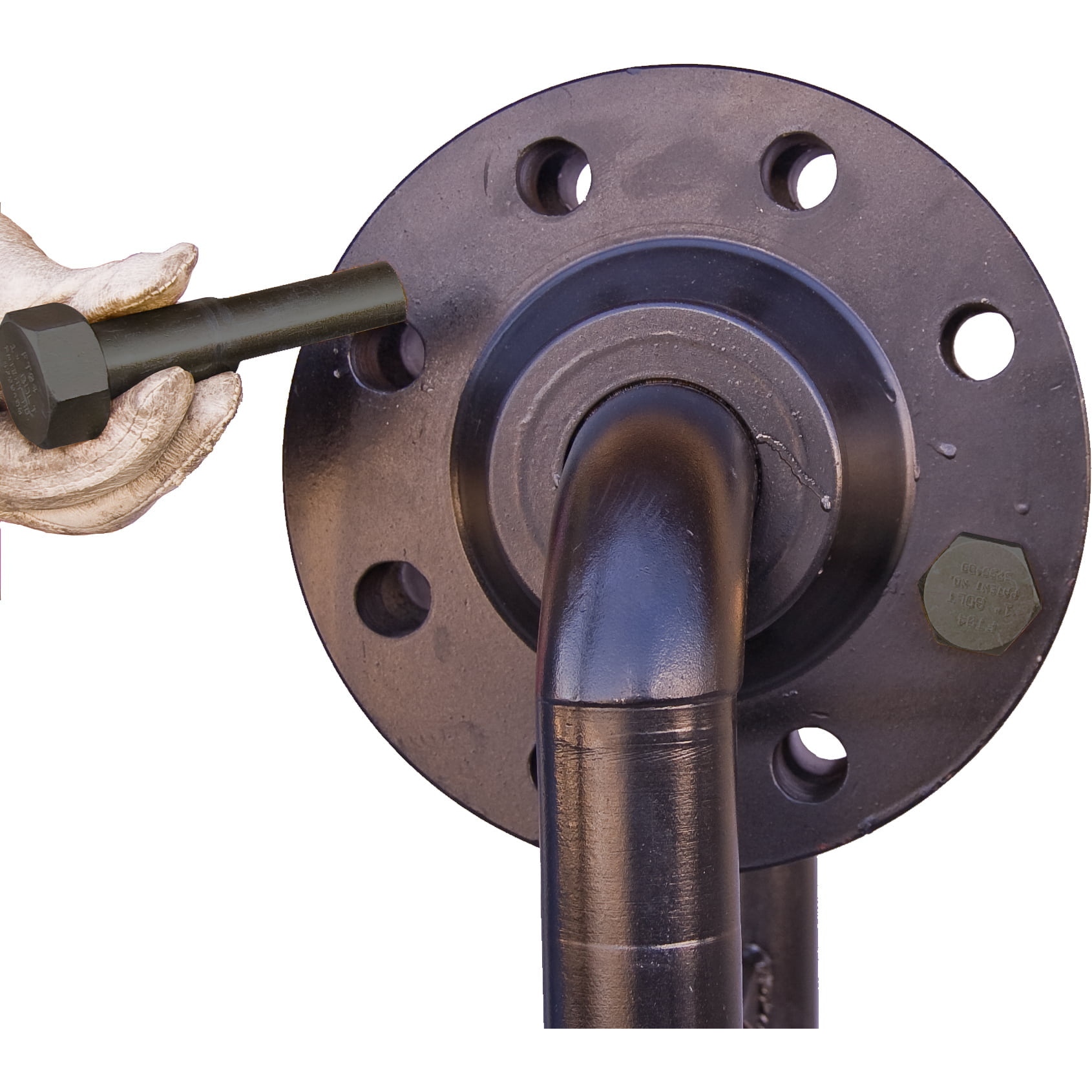

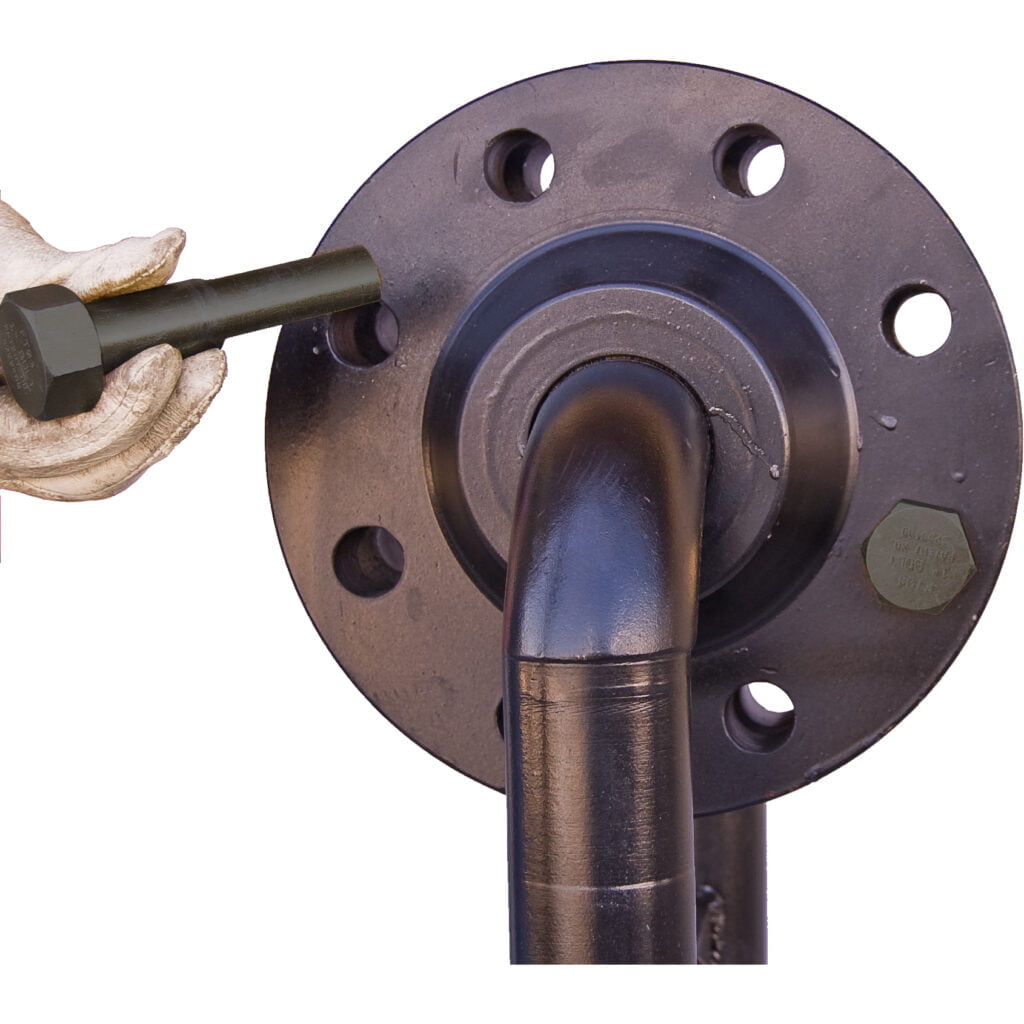

The Petol™ Flange Alignment Pin from SMP is a safe, fast, and effective tool for aligning flanges. Its patented tapered shaft design eliminates the need for hammering or prying when lining up flange bolt holes—removing the struggle often associated with drift pins or spud wrenches.

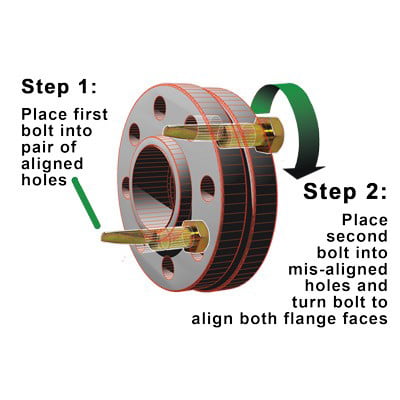

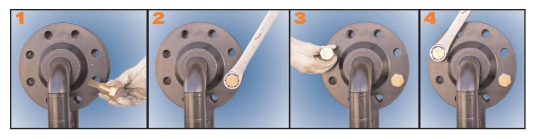

To use, simply find the best bolt hole to insert the bolt-hole specific alignment pin, turn it 180 degrees, and the flange holes will align precisely. To remove the pin, rotate it another 180 degrees—it can then be easily removed by hand.

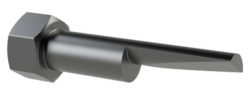

Each Petol flange alignment pin is machined from 4140 heat-treated steel and finished with a black oxide coating for superior corrosion resistance and durability. Extra-long “L” versions are also available for situations where a blind is located between companion flanges.

Petol flange alignment pins are available in a wide range of sizes—from 3/8” to 3-5/8” bolt-hole diameters, in both standard and extra-long lengths—to fit virtually any flange configuration.

Petol flange alignment pins are the fastest and easiest way to line up bolt holes on companion flanges. They are the only alignment pins on the market that compensate for both up-and-down and rotational misalignment, offering unmatched performance and ease of use.

The Petol™ Flange Alignment Pin from SMP exemplifies SMP’s commitment to providing safer, more efficient, and more reliable tools for industrial maintenance applications.

Bolt-HOLE size of your flange*

(NOT THE STUD SIZE)

[Bolt-Hole size = Stud size + 1/8”]

Petol flange alignment pins from SMP are the fastest and easiest way to line up bolt holes on companion flanges. Petol flange alignment pins are the only flange alignment pins on the market that compensate for up and down, as well as rotational misalignment. The simplicity of the Petol flange alignment pins make them the most affordable flange alignment solution on the market.

Petol flange alignment pins are another example of SMP’s dedication to bringing safer and more efficient maintenance tools to the industrial market.

Features

- Completely Insert Pin into largest open bold hole

- Turn 180 Degrees

- Insert 2nd pin into bolt hole on opposite side

- Turn the other pin 180 degrees (Flanges will be perfectly aligned)